Automated PCB Stackup Design and Verification

Manage the PCB stackup design process from concept to fabrication

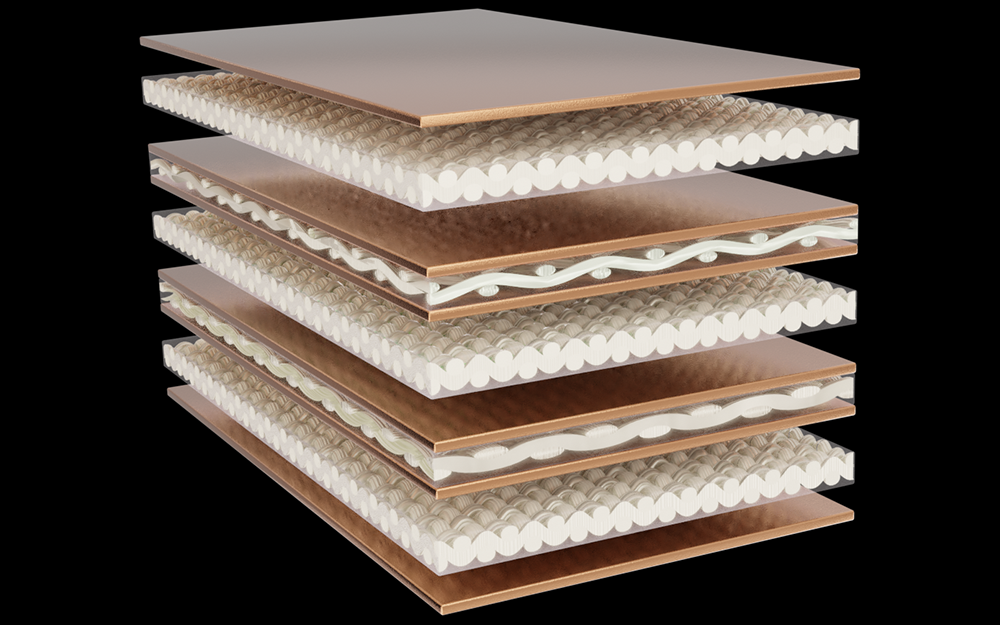

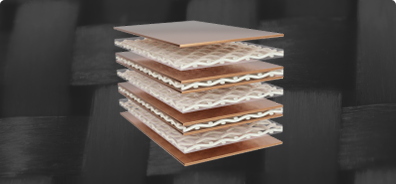

Stackup Design

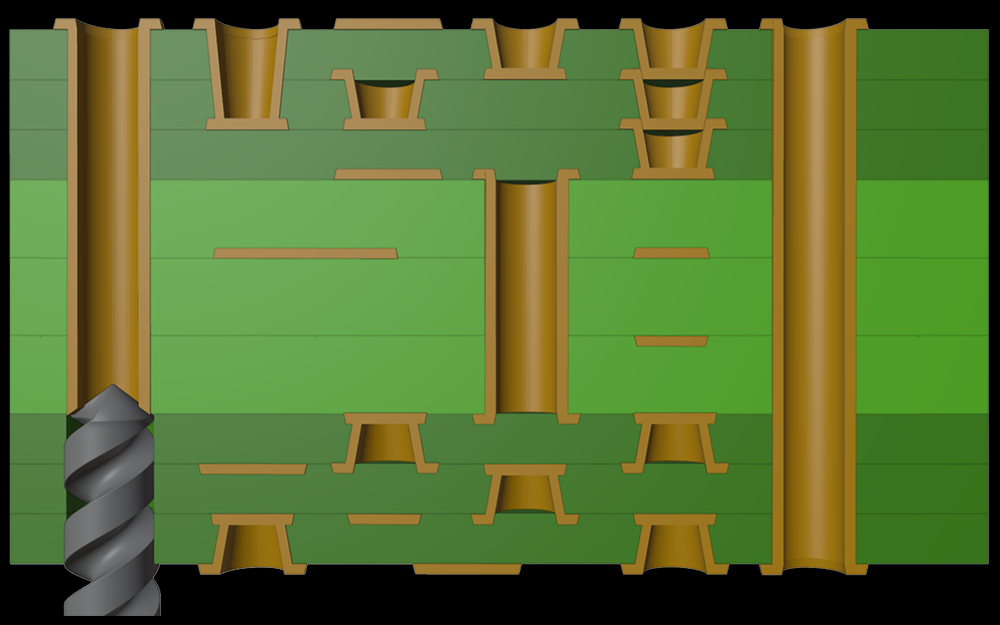

Z-zero PCB stackup design software enables you to design for Zo, Zdiff, insertion loss, and via planning with automation that help you create stackups that are optimized for both signal integrity and power integrity

PCB Stackup Verification

Z-planner Enterprise provides a direct, automated means of comparing fabricator stackups against specifications, including comprehensive DFM and DFSI checking.

PCB Material Selection

The most comprehensive PCB materials library in the industry, including frequency-dependent Dk and Df for major high-speed PCB laminates out of the box. Detailed copper roughness data. Match materials for potential cost reductions. Filter on every material parameter you can think of.

PCB Software Interfaces

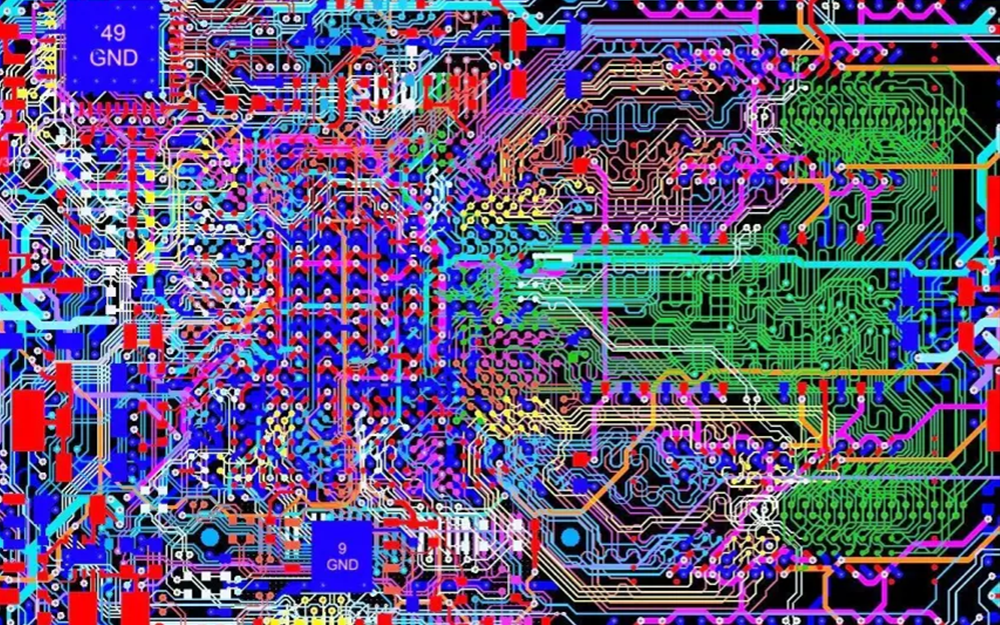

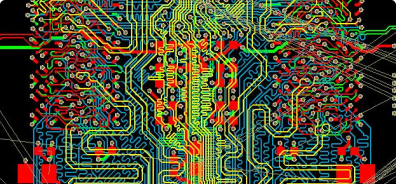

Z-planner Enterprise includes import/export utilities for 18 PCB stackup formats, eliminating the tedious, error-prone process of entering stackups from PDFs. Supported formats include Excel, IPC-2581, HyperLynx, InStack, Polar, Xpedition, and Altium Designer.

PCB Software

PCB Interfaces

PCB Materials

About Z-zero

As signaling speeds increase, manufacturing details are critical in signal integrity simulation and Z-zero software eliminates communication issues between hardware design teams and the PCB supply chain.

Z-zero enhances the stackup design process with a field-solver enabled loss-planning environment, and a complete dielectric materials library — all seamlessly interfaced to the most popular signal-integrity software.

Contact Us

Frequently Asked Questions

- Technical Questions

- General Questions

- Currently, Z-planner imports and exports the HyperLynx format (.STK, .FFS), as well as IPC-2581 and ODB++ formats.

- We’re working on interfaces to Keysight ADS, Sigrity Speed2000, Simberian Simbeor and SiSoft.

Testimonials