Z-SOLVER™

Z-solver

Sometimes you just need quick answers from datasheet parameters and what-if topologies. Z-solver™ provides the most reasonably priced path to making tradeoffs between Dk, Df, trace topologies, and spacing. Results include impedance, differential impedance, propagation delay, and loss vs. frequency.

DOWNLOAD EVAL BUY IT NOW

Z-solver Includes

How Z-solver is used

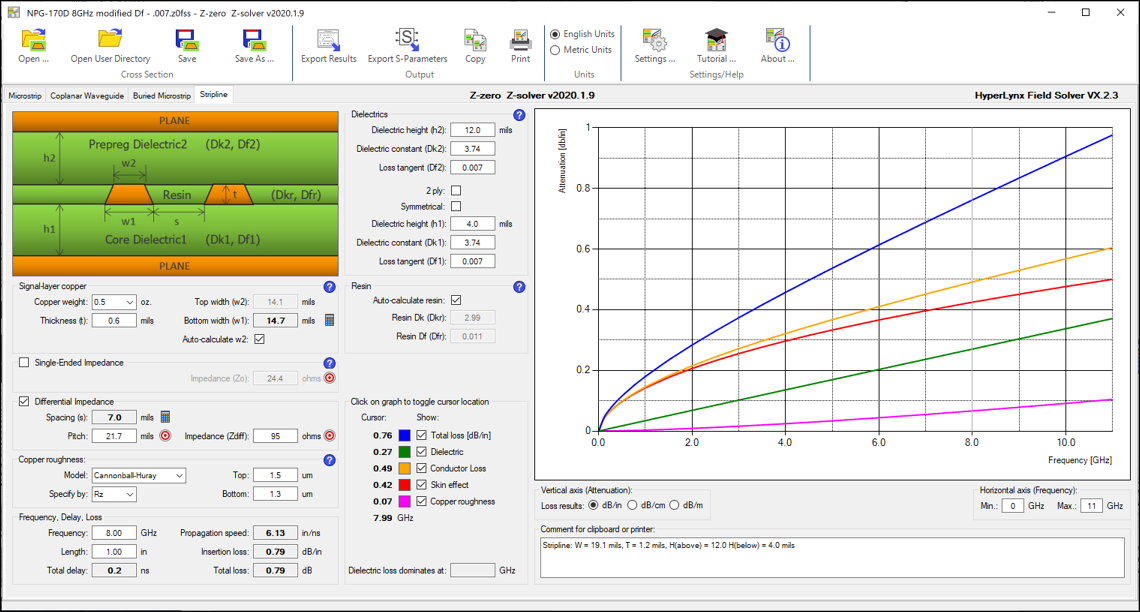

There are a lot of factors to juggle to stay on top of the parameters that contribute to loss, including frequency, copper weight, resin system, glass characteristics, dielectric thickness, trace width, copper roughness, and fabricator processing all contribute to the discussion.

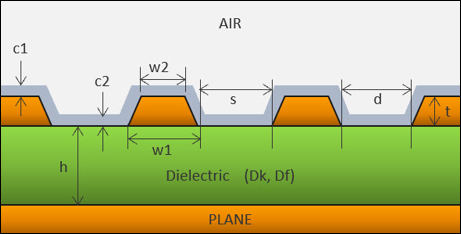

Co-planar waveguide

Co-planar waveguide

It’s common in high-speed PCB design to build test boards with defined geometries across multiple laminate vendors, materials, and fabricators, but the process of doing so takes about six months from concept to completion. In today’s design environment, who can wait that long for concrete answers? A lot of hardware design teams don’t have the luxury of long lead times, where straightforward questions take multiple months to answer.

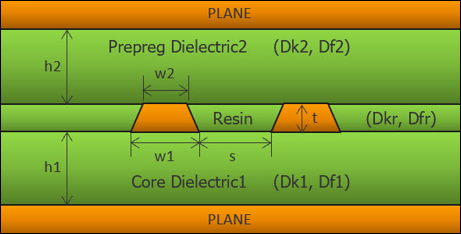

Stripline View

Stripline View

Z-solver allows designers to make tradeoffs early in the system-design process, including frequency, interconnect loss budgets, and the knobs that designers control, including resin system, cost, copper roughness, and trace length.

Key Benefits of Z-solver

HyperLynx field solver

Automated impedance goal seeking

S-parameter channel-model export

Solder mask and dual-ply prepreg modeling

Single-ended and differential impedance

Propagation speed and total-delay simulation

Detailed modeling of etch effects

Detailed cross-section analysis of microstrips, buried microstrips, co-planar waveguides, and striplines

Simulate insertion loss, total channel loss, and a detailed breakdown of dielectric and conductor loss, skin effect and copper roughness, including Cannonball-Huray

Download the Datasheet: